From soft clay to stoneware… The dish.

It all starts with a humble lump of soft clay.

However, it's a process. We will walk you through the steps so you can see the beautiful transformation that a lump of clay goes through to become stoneware dish.

To make a dish…

First and foremost, it's all about the clay.

The clay must be soft, malleable and pliable and easily worked.

Smash and Roll

Each and every single one of Muddy Moses and Mom’s clay creations start out as a humble lump of clay. The clay is cut, wedged, and rolled into a brand-new shape.

Cut and Shape

Once the moist clay is flat, we cut it with a “cookie cutter” or trace out the pattern of the soap dish we want to make.

Ms. Jenny loves leaves...

One of my favorite pass times is to walk and pick up leaves. My favorite leaves are Red oaks and heart shaped leaves. The leaf is rolled into the clay and then traced out to create a leaf cut out.

Stamp the Clay

The cut out is then stamped with our name's sake. It is them turned over and stamped with its own personal stamp of an animal, flower, reptile etc.…

the possibilities are endless.

Form and mold the clay.

The clay cut out is then molded into a drying tray. It needs to be completely dry out, and that takes a few days.

Trim and smooth

Once it dries, we unmold and wipe the clay dish down to eliminate any sharp or misshaped edges.

Bisk fire…

Bisk fire… Into the kiln the dry dishes go for their first firing! This firing will harden the clay, burning away impurities and the leaves ...

They will fire up to 1915 degrees. Once they come out of this kiln fire, they are rock hard and porous.

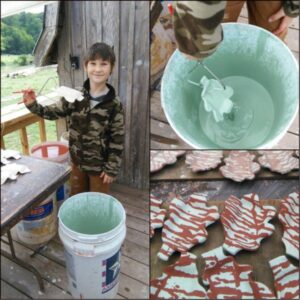

The Messy Middle...

Once cooled, the bisk soap, dishes are ready to be dunked into the buckets of are specially mixed glazes.

It looks backwards, dunking the perfectly good soap dish into this muddy slurry. But here you have to learn to trust the process. Keep going.

Hand paint, Waxed and dip.

The bottoms must be waxed with a special wax. So, they don't stick to the bottom of the kiln.

The stamped image on the soap dish are hand painted, thus making each one of them unique and special.

After the soap dishes are waxed and hand painted, the dishes dipped into the muddy slurry, we call glaze.

Glaze fire.

Now it is Glaze fire time. The mud and mineral covered dish will be returned to the kiln to be fired up to 2185°. The porous dish is transformed into a beautiful stone ware.

Transformation happens at just the right temperatures, not too much to ruin it. But just enough for the clay to cure, reaching the desired density for a stoneware piece and the glaze minerals to melt.

Unloading The kiln after a glaze fire…

In the Stevens family unloading the kiln was akin to Christmas morning. Way back when, TJ, Ms. Jenny and their young boys would gather round to unload the kiln and the expectations and excitement were just like Christmas morning as you rip into that special package… when you crack that kiln top to see the beautiful surprise that awaits…

(photo)

Even to this day it is exciting to open a fresh new load of pottery…

Time to enjoy.

Our clay soap dishes are functional and were made to meet a need. We see each one of them as a direct reflection of our family's passion. One that has been inspired by creativity, the joy of making of memories, the desire to work together, learning life skills and teaching traditional skills and values.

Making a soap dish can be a messy but rewarding task. Moses and I love working with the clay and seeing it Change shape and type form. Working with clay is a transformational process that keeps us humble. As we know, we are just works of clay ourselves…

I love the way Isaiah 64:8 say it...

“But now, O Lord, thou art our father; we are the clay, and thou our potter; and we all are the work of thy hand.”

(photo)

Every day I am still learning to trust the process even in the messy middles, during the muddy dips, times of intense heat and pressure. And in the end, if I don't faint and fall away, I will see the beauty from the process as all of it come to fruition.

Enjoy and God Bless, Ms. Jenny